Divex Asia Pacific working with Analox ACG Technology

When Divex Asia Pacific (DAP) was awarded the Royal Australian Navy (RAN) submarine rescue contract, the company was tasked with finding a better way to monitor the air quality of B-type rescue chambers. Having a long and productive working relationship with the Analox Group, it was a natural choice for DAP to contact the Analox Team to take on the RAN’s requirement.

Previously, air quality tests by the RAN were done on a 3-month schedule using colorimetric tubes. This method did not meet the RAN standards and was actually susceptible to human error possible when having staff evaluate the different shades and colors.

Upon contacting the Analox Team, DAP representatives had a simple, but critical list of requirements for gas analyzing units to be used by the RAN:

- Unit for Analyzing Compressed Gas

- Unit provides 24/7 monitoring

- Unit delivers simple, easy to access data

The Analox Group pioneered technology that meets each element of these important criteria. The Analox ACG and the enhanced ACG+ units both provide effective solutions to the DAP inquiry.

Analox’s proprietary ACG technology allows for compressed breathing air to be monitored for up to five different contaminants simultaneously and continuously. The Analox ACG technology delivers reliable and consistent analysis the military standards demand.

Military professionals appreciate the ability to measure O2, CO, CO2, VOCs and water vapor simultaneously. This solution is not only cost-effective, it is also far less expensive to operate than procedures that require cumbersome and fragile test tubes that don’t deliver the continuous results newer standards are beginning to require.

The System and How DAP Used It:

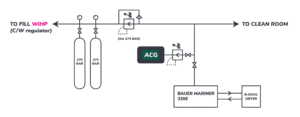

DAP configured the ACG system using a Bauer 320E compressor and a 275 bar bank of cylinders.

The ACG unit was mounted onto the pipe assembly after the compressor and before the split regulators (one filtering to the clean room and the other to the cylinder bank). Please reference the diagram below.

Analox ACG technology is currently being used on multiple RAN vessels to monitor compressed breathing air, and deliver continuous safety scans that meet exacting RAN standards.

The Analox Group has worked with Divex Asia Pacific for more than 30 years.

The original ACG installation was handled by DAP senior staff, who quickly saw the many advantages the ACG system provides.

He outlined the top three:

- The ACG system assists in compressor maintenance. (During the initial test) The ACG tripped the dewpoint alarm. We changed the filters immediately and that rectified the issue straight away. A real-time alarm is so much better than a 3-month sample.

- With other filler cartridges, DAP was achieving approximately 20 hours of use. With the ACG unit and the cooler/dryer system in place, this increased to 40 hours use per cartridge.

- The ACG is really easy to operate. It is straight-forward to use. The calibration procedure is quick and efficient.

Click here for more information on the impressive Analox ACG+ system.