Carbon Dioxide (CO2) accounts for approximately 0.03% of air by volume. It is a colorless gas with no smell or taste.

Carbon dioxide is a colorless and odorless gas, which is present in the air we breathe, in very low concentrations. Classified as a ‘substance hazardous to health’ by the Health and Safety Executive – in higher concentrations carbon dioxide becomes harmful to health, and has proved to be fatal in many circumstances.

One of the biggest dangers of carbon dioxide is the fact that it is a ‘silent killer’ as it simply cannot be detected by humans, even at the highest of concentrations by our senses alone. Carbon dioxide can be detected with CO2 Monitors.

Carbon Dioxide Solutions

Analox offers a choice of wall mount or portable Carbon dioxide (CO2) monitoring solutions.

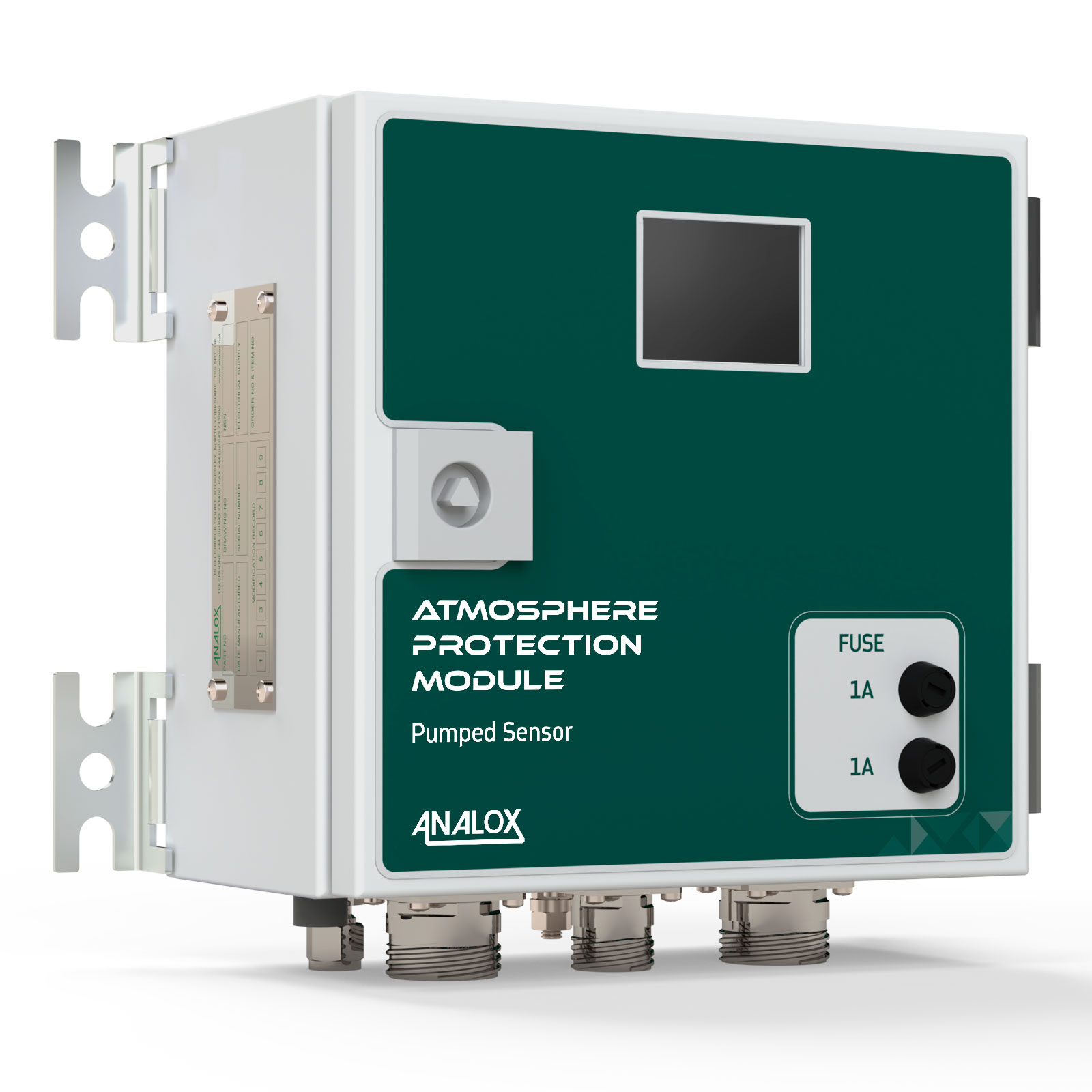

A configurable modular atmosphere monitoring system for submarines and surface ships.

A multi-gas analyzer to measure: oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), Volatile Organic Compounds (VOC’s) and Dew Point in compressed air. The unit can be wall mounted or used as a portable system.

If you need a simple, ready to install and cost-effective gas safety monitor – we’ve got you covered.

The Ax60+ is easy to install and already programmed for your local regulations.

Experience unmatched gas detection, precision and safety with the Analox Ax60+ Cultivate – Your ultimate solution for reliable monitoring in agricultural environments.

A wall mountable carbon dioxide (CO2) monitor and alarm.

The DOM can be retro fitted to any existing Ax60+ installations and provides real-time monitoring of the Ax60+ and communicates with customers remote systems such as a Building Management System (BMS).

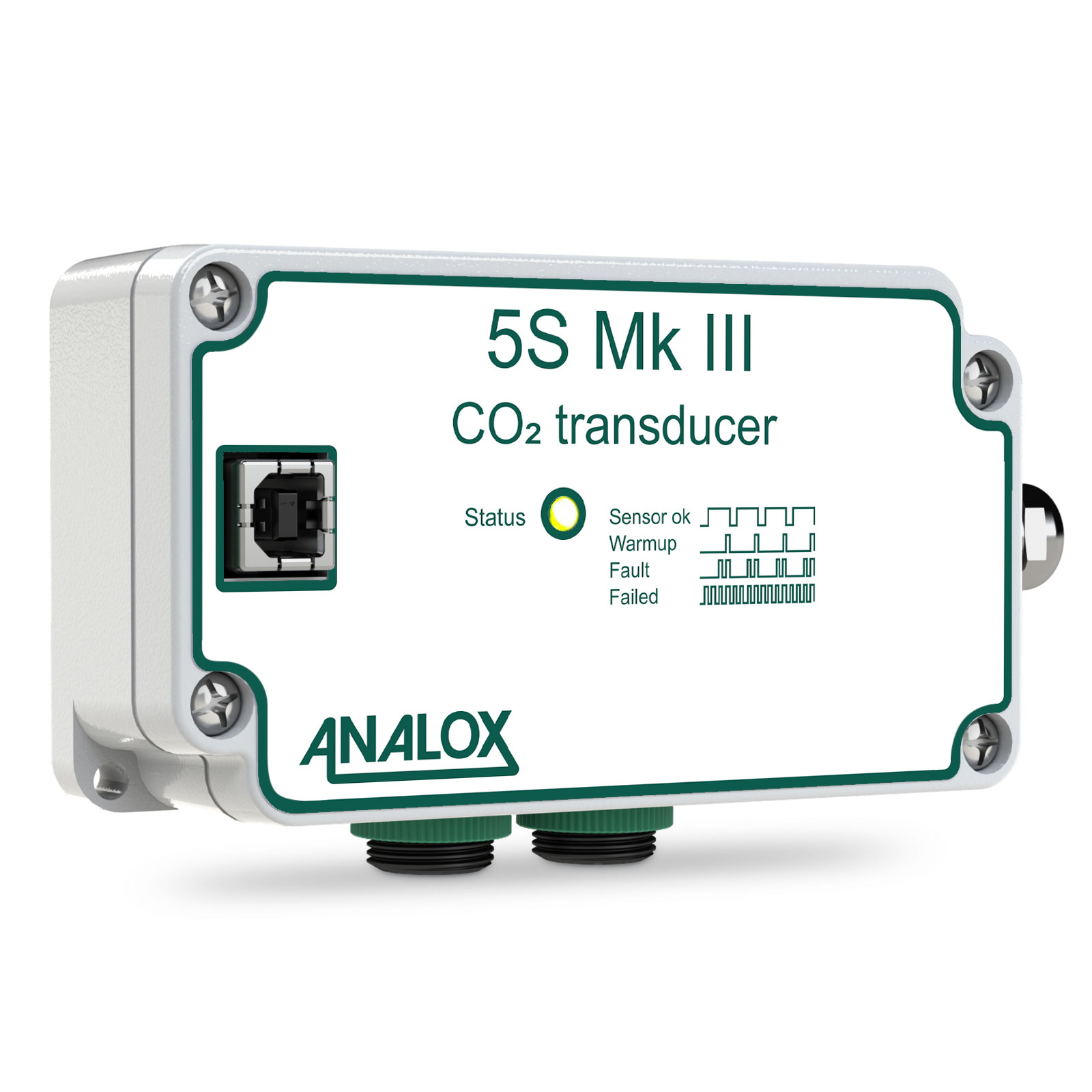

A single gas NDIR (Non-Dispersive infrared) sensor for carbon dioxide (CO2).

A single point wall mounted safety monitor for carbon dioxide (CO2) enrichment. Typically found in restaurants, pubs, bars, fast food establishments, breweries, hospitality venues, laboratories and medical centers.

Due to American legislation, this is not suitable for the American market, please look at the Ax60+.

A portable, personal safety monitor for carbon dioxide (CO2) enrichment.

A portable, personal safety monitor for both carbon dioxide (CO2) enrichment and oxygen (O2) enrichment and depletion.

A compact portable analyzer used as a backup monitor on board submarines and at altitude. The unit can simultaneously sense both oxygen (O2) and carbon dioxide (CO2), whilst providing pressure corrected readings for both.

Air Quality Guardian, A portable air quality monitor alerting you to the need to ventilate your area specifically to measure levels of CO2.

A panel mount, safety monitor for oxygen (O2) and carbon dioxide (CO2)

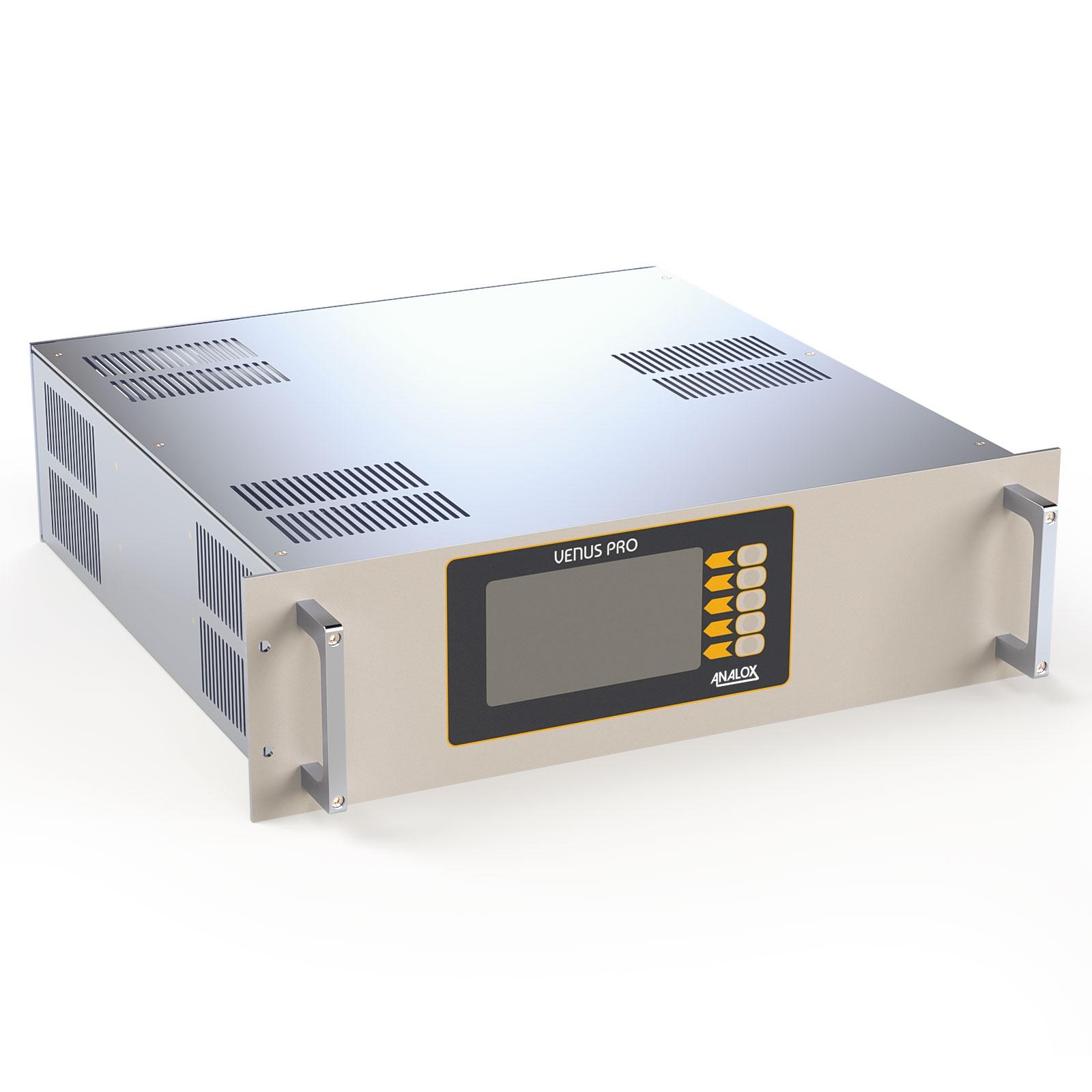

A process gas analyzer for single or multi-gas monitoring.

The SDA carbon dioxide (CO2) monitor provides reliable carbon dioxide (CO2) monitoring to maintain a comfortable and safe saturation diving chamber.

A compact, highly accurate electrochemical oxygen (O2) and NDIR carbon dioxide (CO2) sensor designed for vehicles operating in the upper atmosphere.

Carbon Dioxide (CO2)

Exposure to elevated levels of carbon dioxide has the following effects:

- 250-350 ppm: Normal, outside air-breathing level.

- 350 – 1,000 ppm: Normal, indoor air-breathing level.

- 1,000 – 2000 ppm: Elevated levels in poor quality air, associated with drowsiness.

- 2,000-5,000 ppm: High Levels in Poor Air: dizziness, nausea, increased heart rate

- >5,000 ppm: UK Long Term Exposure Limit (8 Hour Reference Period)

- >15,000 ppm: UK Short Term Exposure Limit

In most workplaces and facilities, it’s the humans within the facility who are responsible for most of the carbon dioxide in the immediate atmosphere. Although typically safe in these concentrations – in poorly ventilated offices, workers can report feeling tired and drowsy where they themselves have contributed to elevated carbon dioxide levels.

Although elevated carbon dioxide levels can be a problem in poorly ventilated office spaces, carbon dioxide is only a danger to life in workplaces and premises that either store or use carbon dioxide in their day-to-day operations. In these premises, it’s essential that carbon dioxide monitoring and detection is in place, to ensure that the owner of a premises fulfils their duty of care to both employees, customers, and visitors.

Wherever there is carbon dioxide on the premises, there is a risk of potentially fatal carbon dioxide leak. Carbon dioxide leaks happen day in, day out – and often prove fatal. A worker typically enters an environment with high carbon dioxide concentrations, loses consciousness, falls onto the floor – where carbon dioxide concentrations are higher still. Death then occurs through asphyxiation.

It would be a misconception to believe that these accidents only happen in industrial environments, where danger is expected. These deaths and incidents take place in a wide range of environments, including restaurants, bars, and fast food kiosks.

As local regulatory agencies look to increase the safety of workers in enclosed space environments, the need for effective and reliable carbon dioxide (CO2) monitoring has never been more important.

CO2 Calculator

There is a common misconception that if using carbon dioxide (CO2) in your facility you can stay safe by using an oxygen (O2) monitor.

The team here at Analox want to dispel this myth so we can ensure you and your team stay safe when using and storing CO2.

CO2 is a toxic gas meaning that even at relatively low levels it can have dangerous effects on the human body. In the event of a CO2 leak, the CO2 will begin to displace the O2 in the area, however, O2 sensors typically have alarm levels set at around 19.5% and 18% so by the time the CO2 has displaced enough oxygen to trigger these alarm levels the CO2 levels will be dangerously high.

If using CO2, your safety monitor must be a CO2 monitor, this is critical so you are alerted to any leaks at levels which still give you time to take action to keep everyone safe. This also helps to save you money as leaks can be addressed early and in the current times of CO2 shortages, protecting this precious resource is key to any business.

We’ve made this calculator so you can check the resultant O2 levels when the ambient CO2 level changes.

SLOT Specified level of toxicity (1 - 5% of fatalities) SLOD Significant likelihood of death (50% fatalities)

Remember: You CANNOT use an O2 sensor to measure CO2 levels. CO2 levels become hazardous to life long before the CO2 displaces enough O2 for it to trigger an O2 alarm.

How Does Carbon Dioxide Affect the Industries Analox Works With?

Beverage & Hospitality

In the beverage & hospitality industry, the use of industrial equipment poses a great risk for gas leaks and fires. Furthermore, there is greater risk to occupant health in establishments designed for dine-in meals and large gatherings, such as restaurants, hotels, and stadiums. Therefore, these establishments must comply with fire codes and regulations to ensure occupant safety.

Beverage & hospitality is the biggest industry that uses Analox CO2 monitors — and it’s because our monitors are key to maintaining safe, compliant operations. Comply with fire regulations by placing safety monitors in “back of house” spaces, such as kitchens, walk-in coolers, cellars, etc.

Dry Ice

Dry ice has a number of uses. Not only is dry ice used to preserve food and medical supplies during transport, but also to clean military and industrial equipment, vehicles, ships, etc. in a process called “dry ice blasting.” Dry ice is highly effective because it is actually solid, frozen carbon dioxide. Therefore, when dry ice melts in an enclosed area, it takes on its gas form. When spaces are not well-ventilated, high levels of CO2 can cause carbon dioxide poisoning or death.

With wall-mounted and portable safety monitors, Analox makes safe storage and use possible.

Labs and Medical

The use of CO2 is common practice in the medical field. The gas is used during surgeries and in lab equipment, such as IVF incubators. Given the nature of the industry, medical professionals must comply with strict health standards to ensure the safety of their patients and colleagues. Wall-mounted safety monitors are essential in controlling CO2 levels in medical facilities and labs.

Cannabis

Cannabis is becoming increasingly popular for medicinal and recreational use, as states across the nation legalize the drug. Along with water and light, cannabis requires CO2 to complete the photosynthesis process. Using CO2 in a grow room is a common and safe practice — when controlled and monitored. However, a gas leak in a sealed grow room can pose great risk to occupants’ health and safety.

CO2 monitoring is important in the cannabis and agricultural industries. Analox safety monitors ensure safe operations in grow houses.

Gas and Welding Distributors

Gas and welding distributors are regularly exposed to hazardous fumes and gases. Welding equipment releases helium, argon, and CO2 into the air, which — in high levels — can cause suffocation.

Facilities that store gas products must use safety monitors to ensure the health and safety of occupants.

Subscribe to our Analox Newsletter!

Gain exclusive access to the latest news, insights, upcoming product releases in gas safety and efficiency. Be the first to know about our innovative solutions, upcoming events, and expert perspectives. Sign up today!

Fun Fact

Carbon gets its name from the Latin word carbo, which means "coal".