Analox has worked shoulder to shoulder with the food and beverage, as well as the hospitality industry, for over 30 years. These industries are the largest sector to use Analox’s CO2 products in the USA. We provide state of the art gas monitors that are designed to perform effectively while boasting unmatched usability to ensure Simple CO2 Safety.

Our gas detection products keep workers and civilians safe in numerous food and beverage applications when being supplied to industry supply chains of breweries, wineries, fermentation plants, pubs, bars, restaurants, all the way down the ladder to end-users. 90% of restaurants say that they find Analox products through Parts Town, one of our biggest distributors in America.

We have seen the industry grow and develop in many ways over time, but recently the most significant change has come from the food home delivery sector. The sector is also now having to adapt to offer outdoor dining and ensuring you are COVID-secure for indoor dining. Restaurants and fast food chains have also adapted to the home delivery demand.

Since the start of the pandemic, Latin and North America have experienced the greatest rise in online grocery sales. Statistics show approximately 60% of Americans are placing a take-out order from their favorite eateries once a week; This newfound habit is one that we project will only continue to grow.

As of 2024, online grocery sales globally have continued their upward trajectory, surpassing previous records. The United States, in particular, experienced a remarkable surge with a 53% increase in online grocery sales in 2020. This trend is expected to persist, and projections indicate that the market is poised to reach an estimated worth of approximately $150 billion by 2024. The continued growth of online grocery sales reflects evolving consumer preferences and the sustained impact of digital transformation on the retail landscape.

Analox has worked with the food and beverage, as well as the hospitality industry, for over 30 years. These industries are the largest sector to use Analox’s CO2 products in the USA. We provide state of the art gas monitors that are designed to perform effectively while boasting unmatched usability to ensure Simple CO2 Safety.

Our gas detection products keep workers and civilians safe in numerous food and beverage applications when being supplied to industry supply chains of breweries, wineries, fermentation plants, pubs, bars, restaurants, all the way down the ladder to end-users. 90% of restaurants say that they find Analox products through Parts Town, one of our biggest distributors in America.

We have seen the industry grow and develop in many ways over time, but recently the most significant change has come from the food home delivery sector. Restaurants and fast food chains have also adapted to the home delivery demand.

Since the start of the pandemic, Latin and North America have experienced the greatest rise in online grocery sales. Statistics show approximately 60% of Americans are placing a take-out order from their favorite eateries once a week; This newfound habit is one that we project will only continue to grow.

As of 2024, online grocery sales globally have continued their upward trajectory, surpassing previous records. The United States, in particular, experienced a remarkable surge with a 53% increase in online grocery sales in 2020. This trend is expected to persist, and projections indicate that the market is poised to reach an estimated worth of approximately $150 billion by 2024. The continued growth of online grocery sales reflects evolving consumer preferences and the sustained impact of digital transformation on the retail landscape.

Memberships & Accreditations

Carbon Dioxide Solutions

Fermentation within the production of alcoholic drinks, storing and bottling of carbonated beverages as well as serving draft beverages all produce and use carbon dioxide (CO2). Within Modified Atmosphere Packaging (MAP) it can also be used to help preserve food, freeze or chill it.

Carbon dioxide (CO2) cannot be detected by human senses and as little as 0.5% in the atmosphere can affect the human body. Protect yourself and your team by fitting a carbon dioxide (CO2) monitor.

If you need a simple, ready to install and cost-effective gas safety monitor – we’ve got you covered.

The Ax60+ is easy to install and already programmed for your local regulations.

The DOM can be retro fitted to any existing Ax60+ installations and provides real-time monitoring of the Ax60+ and communicates with customers remote systems such as a Building Management System (BMS).

A wall mountable carbon dioxide (CO2) monitor and alarm.

A single point wall mounted safety monitor for carbon dioxide (CO2) enrichment. Typically found in restaurants, pubs, bars, fast food establishments, breweries, hospitality venues, laboratories and medical centers.

Due to American legislation, this is not suitable for the American market, please look at the Ax60+.

A portable, personal safety monitor for carbon dioxide (CO2) enrichment.

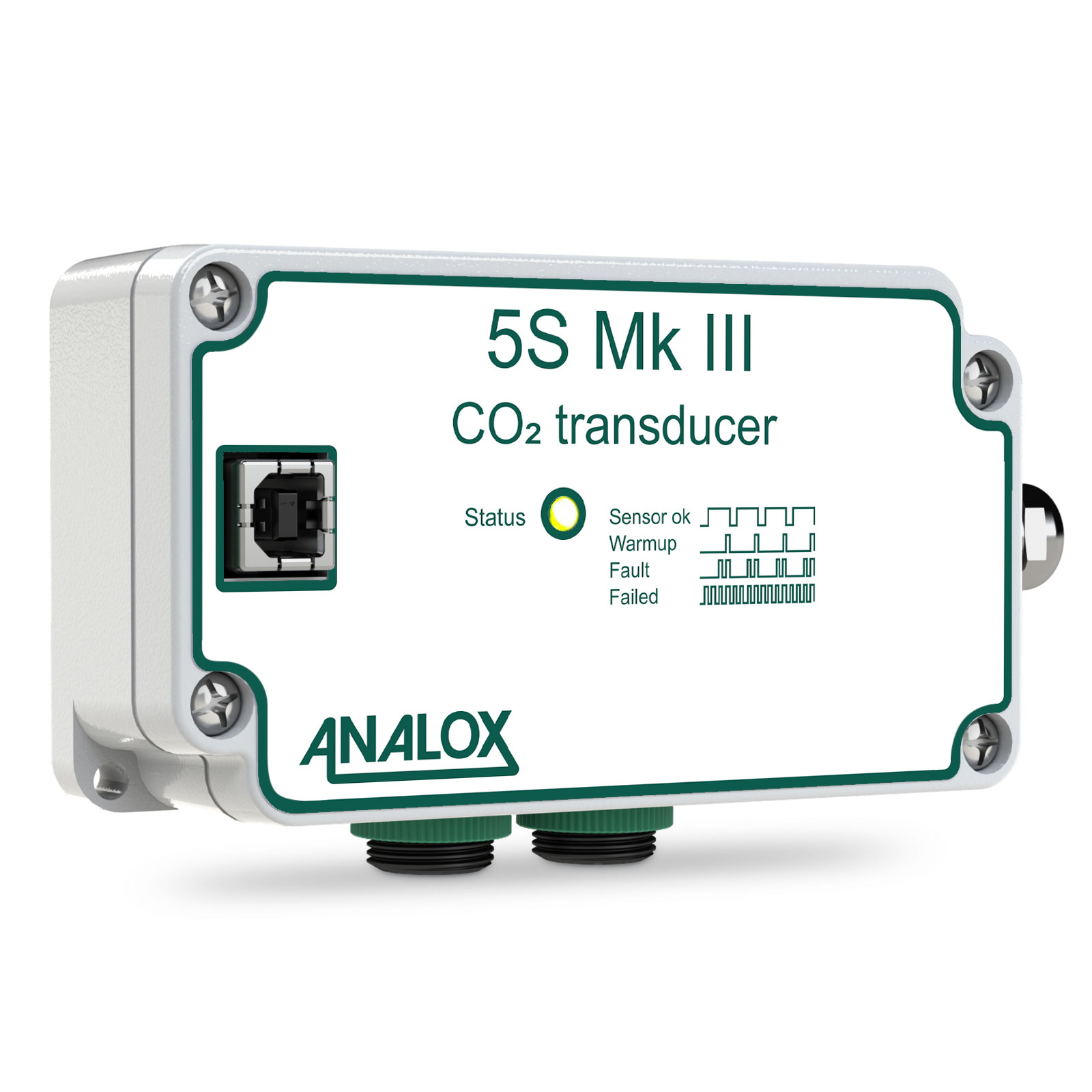

A single gas NDIR (Non-Dispersive infrared) sensor for carbon dioxide (CO2).

Oxygen Solutions

If you use an inert gas, such as nitrogen (N2) in brewing, dispense applications to make a smooth beer or in modified atmosphere packaging (MAP) to preserve foods by chilling, freezing or pressurizing packaging then you need an oxygen (O2) monitor.

If a nitrogen (N2) leak occurs it can displace the oxygen (O2) in the air you breathe which can be fatal. Analox offers a choice of wall mount or portable solutions to make sure that doesn’t happen.

If you need a simple, ready to install and cost-effective gas safety monitor – we’ve got you covered.

The Ax60+ is easy to install and already programmed for your local regulations.

The DOM can be retro fitted to any existing Ax60+ installations and provides real-time monitoring of the Ax60+ and communicates with customers remote systems such as a Building Management System (BMS).

A single point wall mountable safety monitor for oxygen (O2) depletion. This uses a partial pressure oxygen (O2) sensor so it is not cross sensitive to helium (He) ingress.

A single point wall mount safety monitor for oxygen (O2) depletion and enrichment that has a ppO2 sensor.

A portable, personal safety monitor for both carbon dioxide (CO2) enrichment and oxygen (O2) enrichment and depletion.

Multi Gas Solution

If you are using multiple gases within Modified Atmosphere Packaging (MAP) or are looking for a dual gas analyzer in your brewery, look no further.

If you need a simple, ready to install and cost-effective gas safety monitor – we’ve got you covered.

The Ax60+ is easy to install and already programmed for your local regulations.

The DOM can be retro fitted to any existing Ax60+ installations and provides real-time monitoring of the Ax60+ and communicates with customers remote systems such as a Building Management System (BMS).

A portable, personal safety monitor for both carbon dioxide (CO2) enrichment and oxygen (O2) enrichment and depletion.

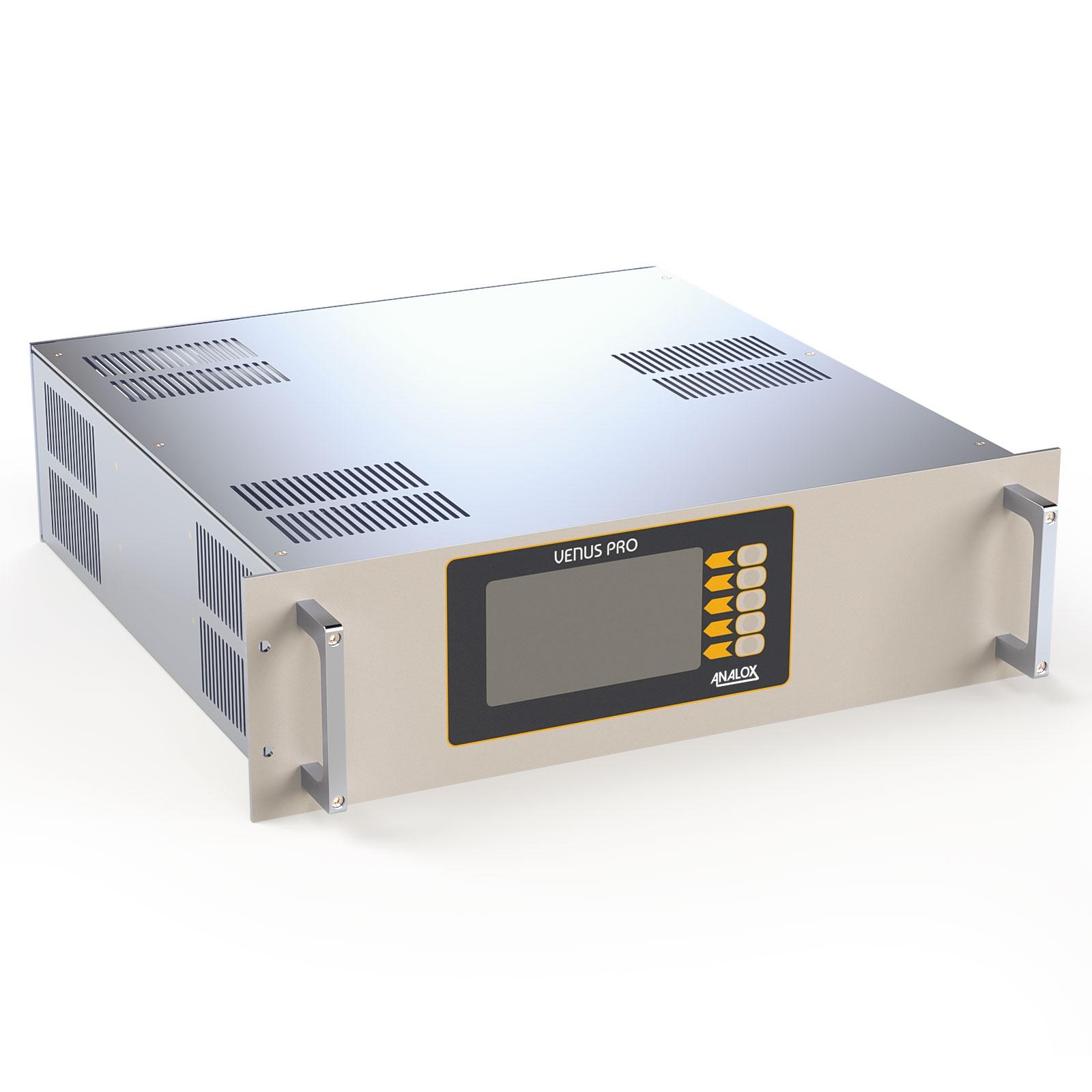

A process gas analyzer for single or multi-gas monitoring.

Modified Atmosphere Packaging (MAP)

The proof was in the pudding, now it’s in the packaging…

The demand for fresher and longer-lasting products in the food and beverage sector is constantly increasing. Food products are travelling further afield, reaching new customers in different destinations. This demand brings a need for better quality control methods, as well as the implementation of new technologies.

Arguably the most popular method involves Modified Atmosphere Packaging (MAP). This is when the atmosphere inside the packaging is modified in order to increase the shelf life of the product, retaining freshness, and preventing microbes from growing.

MAP works on the basis that gases in contact with the product are replaced by controlled gaseous mixtures, which in turn flushes air from the packaging. Although it differs from product to product, the most commonly used gases include carbon dioxide, oxygen, and nitrogen, these gases help to combat bacteria and stop oxidation of the food.

Affected Facilities

In the food and beverage industry, the use of gas-emitting industrial equipment poses risk to occupant health when facility owners fail to control and monitor gas levels. To ensure occupant safety, these facilities must comply with fire codes and regulations by using safety monitors in “back of house” spaces:

Bars/Restaurants

- Quick serve restaurants

- Fast casual restaurants

- Full-service bars & restaurants

Stadiums

- Kitchens

- Food preparation stations

Food and beverage serving facilities play host to many different gases. For example, a mix of carbon dioxide (CO2) and nitrogen (N2) are both used to create the creamy carbonated texture of Guinness. These gases are also essential to the quality of the finished beer and prolonging shelf-life stability.

The reason why carbon dioxide is used in fizzy drinks is because of its solubility in liquid. Around 1.5 liters of carbon dioxide can be dissolved in just one liter of water – and when carbon dioxide is combined with a liquid, it forms Carbonic Acid – which gives us the fizz.

Though these gases give us the food and beverages we love, they pose a silent threat in enclosed spaces like walk-in coolers and cellars. With nowhere for these gases to go, high levels of CO2 or N2 can cause illness or death in enclosed spaces. Safety monitors ensure smooth, compliant operations.

Analox has worked alongside the food and beverage industry for almost 40 years and has developed a range of reliable, accurate and easy to use gas safety monitors for your restaurants, pubs, bars and fast food establishments meaning that you can stay open and safely run “business as usual” without having to worry about dangerous gases.

Where do I put my CO2 and O2 monitors?

As the carbon dioxide that leaks from a gas cylinder is denser than air, it’s important to place CO2 monitors low to the ground – where they can monitor the areas with the highest concentration of carbon dioxide and alert you to a leak as soon as it starts, so you don’t waste any CO2.

O2 monitors should be installed at normal working head height for the area. It is best practice to carry out a risk assessment to determine the best location in the room based on layout, ventilation, gas sources and air flow.

Due to the volume of gases used in the food and beverage industry, it is commonplace for incidents to occur and sadly, there have also been multiple deaths reported in this industry due to gas leaks. It is important you keep your team safe as well as complying to your local regulations.

Each area of the world regulates the permissible limits for gases such as CO2 and O2. The best and easiest way to stay safe and comply is to use gas monitoring systems, ideally those with a TWA (Time Weighted Average) function. As well as installing gas alarms, all equipment used in the carbonation and preparation of drinks needs to be well maintained – minimizing risks of fatal leaks.

A Meaty Fact

Oxygen is generally used to package meat products as it helps maintain coloring. As soon as the meat is cut, oxygen reacts with the myoglobin and creates the bright red color associated with oxymyoglobin. Nitrites keep meat red by bonding to the myoglobin and acting as a substitute for oxygen. Oxygen and sodium nitrate both turn myoglobin red, but nitrate attaches with a more stable bond and so the color lasts longer.

With so many gases being used within the food manufacturing process, the need for reliable gas monitoring equipment is essential. Analox provides monitors to cover every step of the “Farm to Fork” journey.

Food packaging and storage techniques exploit the properties of atmospheric gases in order to create the optimum conditions for protecting food. The packing phase typically employs a process known as modified atmosphere packaging (MAP), in which the ratio of O2, CO2, and N2 is altered to suit the requirements of the product being packed.

Much of the food we see in our grocery stores and supermarkets arrived there via transportation companies (home delivery and food transportation) by using dry ice to package the foods to keep them fresh or frozen. As produce is traveling further and further around the world to reach its final destination, the freshness and longevity must be upheld, dry ice is a great way to ensure this.

Legislation

States that the 8-hour TWA PEL (level of exposure established as the highest level of exposure an employee may be exposed to CO2 without incurring the risk of adverse health effects) is 5,000ppm and a 30,000ppm limit that must not be exceeded in a 10 minute period. A value of 40,000ppm is considered immediately dangerous to life and health (IDLH value).

Recommended Products: Ax60+, CO2Buddy

This piece of Australian legislation sets a minimum standard for the use of gases in the food and beverage industry. The standard is not just confined to new installations, it also requires any existing equipment to be updated to conform. Employers have an obligation to provide a safe working environment and those choosing to work with Analox can rest assured that they will meet these standards.

Often, CO2 cylinders used for dispensing beverages are kept in confined spaces with limited ventilation. AS5034 specifies that all cellars and storage rooms without natural ventilation need gas monitors installed.

Gas monitors must measure carbon dioxide levels and if an inert gas such as argon or nitrogen is also stored or used, an oxygen monitor should be used. An audible and visible alarm should be installed both inside and outside the area.

Recommended Products: A50, Ax60+, CO2Buddy

The entire Analox Food and Beverage line is designed to reliably and accurately measure the presence of carbon dioxide and depletion of oxygen in restaurants, pubs & bars. Our fixed and portable CO2 and O2 monitors are the culmination of forty years worth of research & development, where we have created a range of easy to use, yet innovative monitors that keep your people safe.

Are you looking for the most suitable gas monitor for your pub? Restaurant? Fast food establishment, stadium or bar? You can view the full range of our food and beverage gas solutions below and as always – if you have any questions please get in touch and we will be more than happy to help.

Subscribe to our Analox Newsletter!

Gain exclusive access to the latest news, insights, upcoming product releases in gas safety and efficiency. Be the first to know about our innovative solutions, upcoming events, and expert perspectives. Sign up today!