Hyper-Gas MkII

HYDROCARBON MONITOR

The only hydrocarbon monitor in the world which can accurately monitor the hydrocarbon levels present in a deep sea diving bell.

Key Features

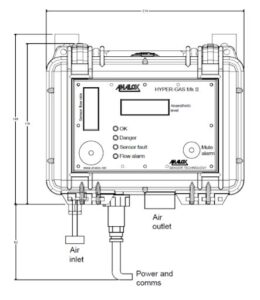

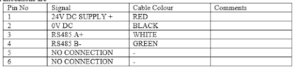

- Compact Bell monitor (which houses the manifold)

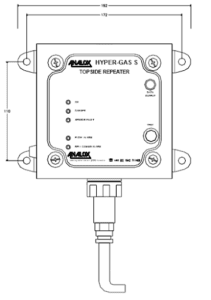

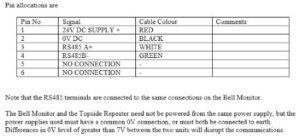

- Topside repeater

- Large, bright full color display

- Datalogging

- Calibration and sensor replacement reminders

- Audible and visual alarms

- Mute function

- Internal filtration and dryer

Industries that use the Hyper-Gas MkII for monitoring hydrocarbons

The Hyper-Gas MkII is the only hydrocarbon monitor in the world which can accurately monitor the hydrocarbon levels present in a deep sea diving bell. Protecting the lives of those who do one of the most dangerous jobs on the planet – Saturation Divers.

DIVING

Saturation Diving; Diving Bell; Oil & Gas; Offshore; Geological research, Oil well intervention, installation and decommissioning; Marine science and surveys

Take a closer look

Hyper-Gas MkII Legislation

The Hyper-Gas MkII is now mandated by The Association of Oil & Gas Producers (OGP) in their “411 Report” which means that any diving contractor working for an OGP member such as Shell, BP, Total or Chevron must have a Hyper-Gas MkII installed in their saturation diving system.

The unit is now used in the majority of operational diving bells and recognised as the accepted best industry practice.

Technical Specification

A deadly mix

After working on the seabed, saturation divers can transport sediment samples (sea mud) back into the diving bell on their boots. This mud contains a deadly mix of hydrocarbons. When these hydrocarbons off-gas into the bell, they have an anesthesia effect on the body, meaning even the most experienced divers would struggle to carry out the simplest of tasks, like putting on their breathing apparatus (BA).

The Hyper-Gas MkII – saving lives at sea since 2006.

Mandated

The unit was designed in 2006 in response to an incident in the North Sea where a diving bell was contaminated with hydrocarbons brought into the bell from the seabed by a diver. Small quantities of hydrocarbons can off gas in the bell atmosphere and act as an aesthetic which could prove potentially fatal for the divers if they are not made aware so that they can take evasive action.

The Hyper-Gas MkII is now mandated by The Association of Oil & Gas Producers (OGP) in their “411 Report” which means that any diving contractor working for an OGP member such as Shell, BP, Total or Chevron must have a Hyper-Gas MkII installed in their saturation diving system.

The unit is now used in the majority of operational diving bells and recognised as the accepted best industry practice.

In safe hands

The Hyper-Gas MkII consists of two parts, a bell monitor which is located inside the diving bell so that the presence of hydrocarbons can be detected rapidly and the divers alerted quickly and a topside repeater which mimics the status of the bell monitor for the dive control team located topside.

The unit will log the levels which can be downloaded and used as critical data for any incident reports and enquiries.

The Hyper-Gas MkII protects the lives of the divers in this hostile environment.

Note: The Hyper-Gas MkII was not designed to monitor hyperbaric levels of hydrogen sulfide (H2S).